استاندارد منهولهای پلی اتیلنی

استاندارد ملی منهول های پلی اتیلنی به شماره 14148 برگرفته از استاندارد ISO 13272 است که تا حدودی با شرایط اقلیمی ایران تطبیق داده شده و به عبارتی بومی سازی شده و خلاصه نکات مهم آن توسط شرکت پلیمر روشان ذیلاٌ آورده شده است.

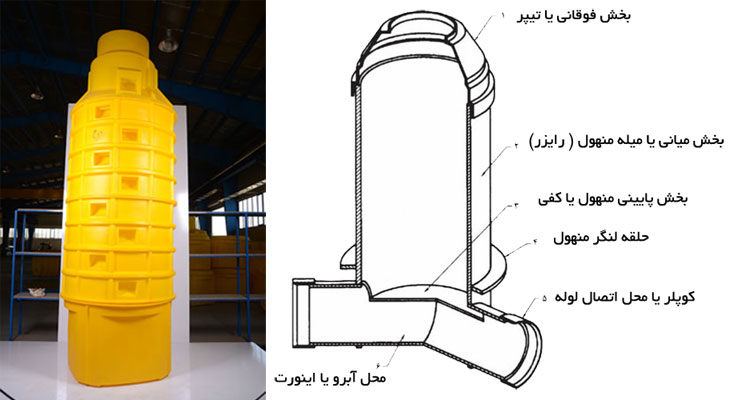

قسمت های اصلی منهول پلی اتیلنی

نکات مهم این استاندارد به شرح زیر می باشد:

1- ساخت منهول های پلیمری از مواد پلی اتیلن (PE)، پلی پروپیلن(PP) و یا PVC قابل انجام است.

2- حداکثر عمق نصب استاندارد پلی اتیلنی 6 متر میباشد و برای عمقهای 4 تا 6 متر دال میانی توصیه شده است.

3- بخش پایه آدم رو (کفی منهول) جزء الزامی منهول بوده و شامل مجاری یکپارچه همراه با سکو میباشد.

4- اجزاء مختلف مجموعه آدم رو میتوانند از مونتاژ قطعات تولید شده از مواد مختلف باشند.

5- مواد سازنده اجزاء منهول پلی اتیلنی بایستی حاوی مواد ضدپرتو فرابنفش باشند و توصیه میشود که انبارش طولانی مدت آدم رو در معرض نور خورشید صورت نگیرد.

6- جهت نرگی و مادگی بکار رفته در سامانه لوله گذاری منهول بایستی قطر، ضخامت دیواره، طول نری ها و تلرانسها سازگار با استانداردهای لوله باشند.

7- اختلاف ارتفاع کف لوله های ورودی و خروجی با کف محل اتصال آدم رو برای لوله های 315 (300) و پایینتر، حداکثر 6 میلی متر و برای لوله های بزرگتر از 315(300) برابر 0.02*DN میلی متر و حداکثر 30 میلی متر میباشد.

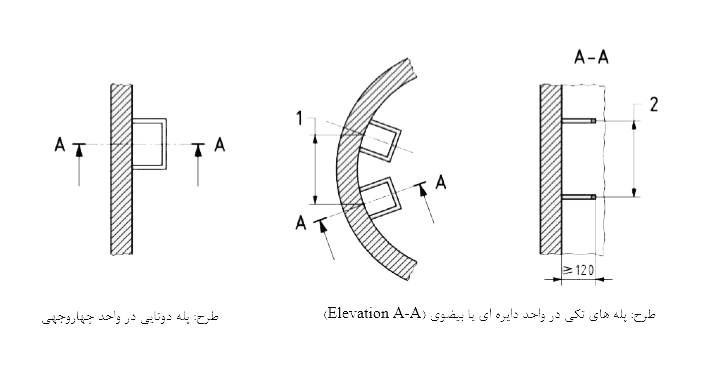

8- حداقل فاصله لبه پله ها از دیواره منهول 140 میلی متر میباشد و فاصله عمودی پله های تکی (چپ و راست) 250 الی 350 میلی متر و فاصله مرکز پله ها از یکدیگر در محدوده 270 تا 300 میلی متر میباشد.

9- استحکام پله های آدم رو برای بارهای عمودی حداقل 2 کیلو نیوتن و مقاومت بیرون کشیدگی آنها (مخصوص پله های نصب شونده) حداقل 1 کیلونیوتن است.

10- سفتی حلقوی فقط برای قطعات میانی آدم رو (میله آدم رو) تعریف می گردد که بزرگتر یا مساوی 2 KPa میباشد.

11- مقاومت ضربه پذیری تنها در بخش پایه منهول تعریف شده که بایستی تحمل سقوط وزنه یک کیلوگرمی از ارتفاع 5/2 متری با شعاع سر وزنه 50 میلی متر را داشته باشد و دچار شکستگی نشود.

12- تحمل فشار منفی 0.1 bar در بخش پایه منهول تعریف میگردد.

13- دوام منهول های پلی اتیلنی حداقل بایستی 50 سال بوده و در این مدت تغییر شکل بیش از 5% نباشد.

14- منهول های جانبی (مماسی) برای لوله های با قطر 1200 میلی متر و به بالا مجاز میباشد.

15- تست پایداری حرارتی (OIT) برای منهول های تولید شده به روش روتاری مولدینگ حداقل 10 دقیقه است.

16- شاخص جریان مذاب (MFI) برای محصولات روتاری 5/4-5/3 میباشد.

17- در صورت وجود بارهای ترافیکی استفاده از دال بتنی مسلح متناسب با بار وارده الزامی است.

18- تولید کنندگان مجاز به استفاده از مواد بازیافتی و غیر بکر نیستند.